Dr. Achim Tegeler, May 2023

Construction of a parallelogram mount for astronomical binoculars

Anyone who, like me, goes through life with a few diopters in front of their eyes, is happy about every incoming photon and every meaningful magnification that makes it easier for the eyes to see astronomical objects. How nice it is to simply observe the moon, planets or even star clusters and double stars with binoculars – possibly even relaxed in a deck chair – if it weren't for the problem of arm fatigue and the shaky image with heavy binoculars. From 10x magnification on, hands-free binoculars without image stabilization are no longer fun – and my astro binoculars magnify 25x and weigh 4.5 kg. Photo tripods are usually overwhelmed. For a long time I had a project in mind to build a mount for astro binonoculars – ideally a parallelogram mount based on the model of the 10Micron Leonardo BM-100, which is of course also available for about 3500 EUR.

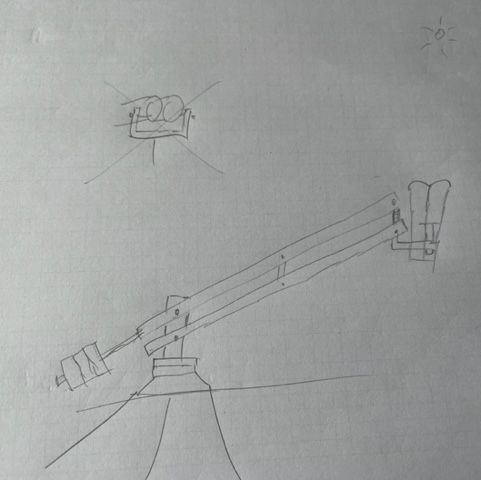

So, after planning, freehand drawing with a glass of red wine and a rough estimation of the size and the corresponding material requirements, it was time to procure materials. It should be aluminum in order to be stable and durable and to remain manageable in terms of weight. The existing Skywatcher EQ5 steel tripod was to serve as a tripod – including the counterweights of the EQ5.

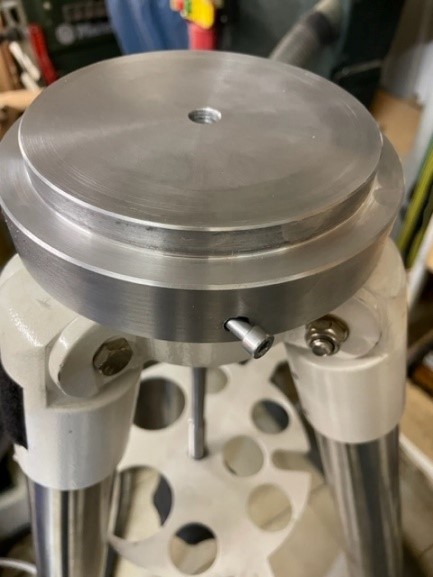

First, the base block was created; all surfaces were milled and the edges were chamfered.

Then the two interlocking base plates were turned on the lathe, on which the block is to be screwed and which will ensure the rotatable connection to the tripod.

In order to prevent unintentional rotation during observation, a locking screw made of brass was created and placed in the upper base plate. This screw then clamps the upper to the lower base plate. A self-made disc made of PTFE foil is placed between the two plates, which is supposed to minimize sliding friction - after all, the total weight of approx. 40 kg loads here during use and generates friction.

From below, of course, the recess for the "north mandrel" fixed to the EQ5 tripod had to be drilled in the base plate and a clamping screw for anti-rotation had to be realised.

The usual clamping screw of the EQ5 mount, which comes from below, is too short for this setup and could not be used, so a new long clamping screw was turned out of stainless steel. This is screwed into the block from below through the two base plates.

The booms are intended to enable observation while standing and therefore had to be long and correspondingly rigid. There should be rounded edges at pivot points – yes, filing was also part of it!

Since the long lever with heavy binoculars exerts considerable forces, the bracket for the counterweights had to be correspondingly generous. Accordingly, an aluminum block was milled here, which is supposed to accommodate a stainless steel rod for pushing the counterweights. The stainless steel rod was screwed into the block via an M16 thread. In order to have better "grip", suitable flat edges were milled in for wrench size (SW) 17. The block was bolted to the longer, upper outriggers via 12 stainless steel screws.

All axles were made of 12mm stainless steel and fastened with handwheel nuts. In the event that the handwheels do not prove useful in operation, they will be replaced by self-locking nuts.

The great thing about parallelogram mounts is that once the object has been placed in the field of view in the sky, it remains in the field of view due to the stable position of the front/carrier plate, even if the viewing height is adjusted for other observers. This spatially stable position is made possible by the parallel displacement of the carrier plate.

At the same time, however, the mounted binoculars should of course also be vertically tiltable to adjust the elevation angle of the object and be rotatable a few degrees horizontally for easier finding of objects. On the front panel, therefore, two axes of rotation had to be planned for the two dimensions. The sliding friction was realized in all bearings in the absence of a favorable source of Teflon with PVC discs – how long they will last remains to be seen.

The horizontal rotation should be done via the sliding bearing of the binocular holder.

Strangely enough, almost all manufacturers of even heavy optics still provide for a 1/4 inch or, at best, a 3/8 inch photo thread to hold the devices (often in relatively soft aluminum). From my point of view, it is downright reckless for heavy optics to rely on these "flimsy screws", especially if you want to set the optics vertically, as in my case on the bracket. Therefore, I had to change that accordingly and make a more stable retaining column with a "decent" thread. The new column was turned, milled and provided with an M12 thread.

When assembled, the whole thing looks like this – yes, it needs 15 kg of counterweight:

The first tough test was the On The Moon Again campaign 2023 – the mount has already proven itself very well here! Maybe this little report will motivate one or the other to tackle a similar project – relaxed observation in any position and tremor-free pictures are simply fun – and so is planning and building!